Experienced procurement teams know there’s no “one-size-fits-all” procurement strategy. Processes must be adapted to individual business needs. Beyond that, they must be adapted to different types of procurement within a business, each demanding unique strategies, technologies, and management techniques.

The two primary procurement categories – direct and indirect procurement – illustrate this perfectly. Direct procurement is directly tied to a company’s production activities and requires a focus on supply chain continuity, quality control, and cost management specific to production needs.

Indirect procurement, in contrast, calls for a different approach. Its focus is on goods and services that support daily business operations but aren’t destined for production. Indirect procurement strategies often prioritize cost reduction, efficiency, and streamlined processes.

This article explores the differences between indirect and direct procurement, their operational importance, and the role of technology and automation in optimizing them.

What is Direct Procurement?

Direct procurement is the acquisition of goods and services that contribute to creating a company’s end product. It encompasses purchasing raw materials, components, and core supplies that are integral to the production process.

Unlike indirect procurement, direct procurement strategy is tightly integrated with the company’s core business activities.

Typically, direct procurement focuses on a series of well-defined processes:

- Identification of needs: The procurement process begins with identifying the materials and components required for production. This step is closely aligned with the company’s production plans and forecasts.

- Supplier selection and management: Next, procurement professionals identify suppliers who can provide the items at the right quality, quantity, and price. They aim to negotiate contracts that ensure a stable supply at an acceptable price.

- Ordering and acquisition: Once suppliers are selected, the procurement team places orders, specifying quantities, delivery schedules, and payment terms.

- Delivery and inventory management: The goods are received, inspected for quality, and stored until needed for production. Effective inventory management aims to eliminate overstocking or stockouts, which can disrupt production.

- Integration into Production: The procured items are then integrated into production. A successful direct procurement system ensures that production schedules are met without delays.

The direct procurement process is often characterized by large purchases, long-term supplier relationships, and contracts critical to the business’s ability to produce its goods. Given its direct impact on the production process and the final product quality, it requires strategic planning and coordination with internal and external stakeholders.

Key Aspects of Direct Procurement

Direct procurement is essential for efficient production, profitability, and maintaining a competitive advantage in the market. Let’s look at some key factors that impact the effectiveness of direct procurement.

Supplier Relationships

Building robust and enduring relationships with key suppliers is vital to effective direct procurement. These relationships are typically long-lasting and involve collaboration for mutual benefit. Effective supplier collaboration can improve material quality, garner favorable terms, and ultimately create a more reliable supply chain.

Strategic Sourcing

Strategic sourcing thoroughly analyzes procurement activities to identify cost savings and efficiency improvement opportunities. It includes evaluating suppliers, assessing the total cost of ownership, and implementing purchasing strategies that align with the company’s business goals.

Cost Management

Businesses typically use should-cost analysis for direct spend, a technique designed to determine the fair value or “should cost” of a product or service.

A should-cost analysis is a systematic approach that breaks down the cost of a product or service into its essential components. This analysis considers various factors, including:

- Material Costs

- Labor Costs

- Overhead Costs

- Profit Margin

By analyzing these components, a company can estimate a product’s cost, assuming reasonable efficiency and profit margins. This benchmark can then be used in negotiations with suppliers to ensure fair and competitive prices.

Supply Chain Coordination

Coordinating the supply chain involves managing the flow of materials from suppliers through the production process to the end customer. It combines procurement, logistics, transportation management, and synchronization of supply with production schedules to ensure timely delivery of products.

Quality Control

Quality control ensures that the materials and components sourced meet the required standards and specifications. It’s essential for maintaining the quality of the final product, and it typically involves rigorous inspection and testing of procured items and collaborating with suppliers to maintain quality standards.

The Strategic Importance of Direct Procurement

Direct procurement is pivotal to a company’s ability to produce high-quality products efficiently and competitively. It influences both the production line and the company’s overall market positioning and profitability.

Failures in direct procurement result in significant supply chain and production disruption, with consequences that can include:

- Production Delays: A shortage of critical materials can halt production lines, leading to delays in order fulfillment and loss of revenue.

- Increased Costs: Inefficiencies in procurement can lead to higher costs, either due to expedited shipping charges or the need to purchase materials at premium prices.

- Quality Issues: Substandard materials can lead to inferior product quality, damaging a company’s reputation and leading to customer attrition.

- Loss of Market Share: Inability to meet market demand due to procurement issues can result in loss of market share to competitors.

For example, consider a smartphone manufacturer. Their success depends on the timely procurement of high-quality components such as chips, screens, and batteries. If a critical microchip supplier fails to deliver on time, the company faces a production bottleneck and must quickly find an alternative supplier.

The manufacturer may have to postpone the launch of new models, losing market share to competitors. Additionally, if the alternate supplier’s chips are of lower quality, it may lead to widespread product failures, damaging the company’s reputation and causing significant financial losses and customer dissatisfaction.

What is Indirect Procurement?

Indirect procurement is the acquisition of goods and services that support a business’s day-to-day operations. These are essential but don’t directly contribute to the company’s primary business activities or the production of its core products.

Indirect procurement typically includes a wide array of items and services, such as office supplies and equipment, IT hardware, maintenance and repair services, software, utilities, cleaning services, and employee training. While not directly contributing to product manufacturing, these products and services are vital for maintaining productive and efficient business operations.

For example, a manufacturing company requires computer software for its design team. Software procurement is classified as indirect procurement because, while essential for business operations, it does not directly contribute to manufacturing the company’s products.

The design team manager or an executive would assess the software options, make a choice, and create a purchase requisition, which would then receive approval before the purchase order is sent to the supplier.

Key Aspects of Indirect Procurement

Indirect procurement strategies involve distinct processes and challenges compared to direct procurement. Understanding these key aspects is crucial for businesses seeking to optimize their indirect procurement processes.

Broader Supply Base

Indirect procurement may involve a broader range of suppliers and products than direct procurement, including diverse goods and services. Managing this varied supply base effectively is essential for quality assurance and cost-effectiveness.

Lower Individual Transaction Values

Transactions are often more frequent, but they have lower values. A mid-sized company might process hundreds of requisition orders, purchase orders, and invoices a month, each of which must be approved, checked, and reconciled. Manual processing costs quickly add up—one reason many businesses invest in procure-to-pay automation solutions.

Compliance and Procurement Policy Enforcement

Buyers must adhere to budgetary constraints, maintain ethical standards, and follow established procurement procedures. The diverse range of products and services typically involved in indirect procurement may bring internal stakeholders into contact with various regulations, including environmental laws, data protection rules, and industry-specific guidelines.

Multiple Internal Stakeholders

The purchasing and approval process is often decentralized, with different departments or units having the autonomy to make purchasing decisions, adding a layer of complexity.

Multiple buyers can make it difficult to maintain consistency and coordination. Departments might engage with different suppliers for similar goods and services, leading to inefficiencies, rogue spending that fails to take advantage of negotiated indirect procurement deals, and a lack of consolidated purchasing power.

For instance, the marketing department might prioritize creative services and digital tools, while the IT department focuses on software and hardware. These varied needs result in multiple buyers making procurement decisions based on their specific departmental priorities, not cross-organizational procurement policies and priorities.

The Strategic Importance of Indirect Procurement

While indirect procurement may not directly contribute to producing a company’s core products, its strategic importance cannot be underestimated. The effective management of indirect procurement maintains smooth operations and optimizes costs, both of which indirectly influence a company’s performance and competitiveness.

Indirect procurement offers significant cost savings and budget optimization opportunities, particularly through process optimization and automation. Unlike direct procurement, where costs are often closely tied to the quality of the final product, indirect procurement allows for more flexibility in finding cost-effective solutions without compromising core business functions.

How Tech is Transforming Direct vs Indirect Procurement

New technologies and procurement automation strategies have transformed the procurement process. While the same tools are often employed in both areas, their applications differ, reflecting direct and indirect procurement’s unique challenges and objectives.

Procurement Software and eProcurement Systems

In direct procurement, procurement software and eProcurement systems are intricately linked with the supply chain and production processes. These tools are used for in-depth supplier relationship management, inventory tracking, and integration with broader systems like enterprise resource planning (ERP) and manufacturing execution systems (MES).

The focus here is on aligning procurement activities closely with production schedules, inventory needs, and demand planning to ensure the supply chain is optimized for efficiency and cost-effectiveness.

In contrast, indirect procurement systems prioritize operational efficiency and ease of transaction processing. They are tailored to manage diverse products and services, simplifying the purchasing process and ensuring smooth transaction flows.

The emphasis is on ease of ordering, managing various suppliers, and efficiently handling the high volume of indirect spend transactions.

Data Analytics

Data analytics is crucial in both procurement types but serves different purposes. In direct procurement, analytics is primarily focused on optimizing the supply chain. It involves assessing supplier performance, analyzing risks, and ensuring that inventory levels are balanced with production needs.

Data analytics is leveraged in indirect procurement processes for spend visibility, uncovering cost-saving opportunities, developing category management strategies, and enhancing the efficiency of the procurement process. The goal here is cost reduction, ensuring compliance with policies and budgets, and identifying areas for process improvement.

Cloud-Based Procurement Platforms

Cloud-based solutions are a common thread in both direct and indirect procurement, offering scalability, flexibility, and real-time data access. These platforms enable seamless collaboration and information sharing across different departments and geographical locations, a crucial feature for coordinating procurement activities and maintaining a holistic view of the organization’s procurement landscape.

SaaS procurement solutions have become intrinsic to many businesses’ procurement strategies. The global procurement as a service market was worth $2 billion in 2021 and is expected to more than double by 2030.

Procurement Automation

While automation is fundamental to both direct and indirect procurement, it varies in focus. In direct procurement, automation is closely tied to aligning procurement with production. It involves automating inventory management and order processing and facilitating seamless integration with production-related systems.

With indirect procurement, automation is typically centered on streamlining routine purchasing activities with integrated product marketplaces, purchase order automation, invoice automation, and policy compliance. The aim is to reduce administrative burden, enforce procurement policies, and efficiently manage the high volume of transactions.

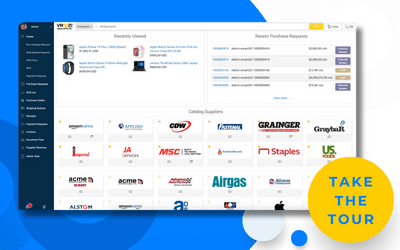

For example, manual processing of purchase requisitions is a common cause of indirect procurement delays. When requisition approvals are postponed, the procurement cycle grinds to a halt. Modern procure-to-pay platforms like Vroozi expedite approvals by routing purchase requisitions to the right person and displaying them in an intuitive interface accessible from any device.

Conclusion: Direct vs Indirect Procurement

We have explored the distinct worlds of direct and indirect procurement, each of which is vital to a business’s overall success and efficiency. Effective direct and indirect spending management contributes to cost savings and operational efficiency. It enhances the company’s ability to adapt to changing markets and maintain a competitive advantage.

Vroozi is an intelligent spend platform that provides integrated solutions for B2B purchasing, payment, and collaboration, including:

- Procure-to-Pay automation

- eProcurement and integrated supplier catalogs

- Purchase order automation

- Invoice automation

- Digital payments

To see Vroozi in action, experience a live version of the app or request a personalized walkthrough from one of our team members.