As interest rates rise, businesses are pivoting and adjusting their spending strategies. And in a business world that’s tightly intertwined, any major buying and selling change can ripple throughout the supply chain—potentially leaving your company exposed to massive losses.

Procurement may need to act fast to avoid the supply chain disruptions that spring from higher interest rates. Here’s how higher interest rates can impact your supply chain, along with the best ways to avoid a financial backslide.

How Higher Interest Rates Sway Supply Chains

Rising interest rates make many procurement professionals nervous, and for good reason. They can shake the supply chain—and force procurement teams to change their procurement strategy. Here are a few ways higher interest rates can influence supply chains:

- Capital can dry up: The cost of capital can increase, and it can become more difficult to secure financing. This can also cause a company to buy less aggressively and risk running into shortages.

- Costs may surge: Suppliers have less access to capital, meaning they may pass on higher costs to buyers. Procurement then has to plan around price increases.

- Budgets dry up faster or get overrun: If your business needs to free up cash and avoid borrowing, it may shrink its budgets—or teams may go over budget more frequently.

- Supply chains can become exposed to risk: Many suppliers react to the higher capital costs by cutting their inventory levels. After all, suppliers want to avoid leaving increasingly costly products sitting on the shelves. Supply chains can become fragile when suppliers reduce inventory levels, putting buyers at risk of running into shortages.

- Shortages vibrate down the chain: Buyers require lower order processing and fulfillment cycle times.

How to Avoid Supply Chain Issues During Higher Interest Rates

We all know how a damaged supply chain can wreck finances. In 2021, companies lost an average of $82 million apiece in some industries. However, there are ways for procurement leaders to avoid supply chain risks in the face of higher interest rates. Here’s how:

Increase spend visibility.

By increasing spend visibility, a procurement team can see how the company is spending and adjust spending based on need. With those details in hand, it’s easier to gain more spend control, keep spend within budgets, and avoid overrunning budgets too fast.

Too often, spend visibility becomes clouded by rogue spending. Often, employees will make purchases with unapproved suppliers. As a result, procurement loses spend control and can’t see where that spend is flowing.

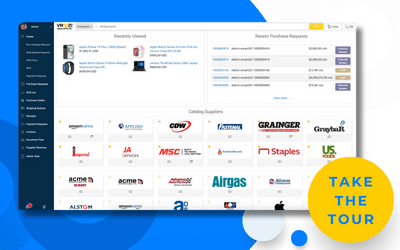

An easy way to boost spend visibility is by adopting a digital procurement marketplace. These marketplaces make it easy for employees to browse, find, and buy goods and services from approved suppliers. Because these platforms are intuitive, more employees use them, and your spend visibility becomes crystal clear.

Use an automated P2P solution.

P2P solutions protect against supply chain disruptions by increasing order velocity and agility. For one, these solutions use machine learning to reduce errors and simplify work. For instance, advanced platforms will automatically complete two- and three-way matching, can create POs, and reduce manual input. In turn, it’s easier to avoid hold-ups and bring in necessary products on time—so you can bypass shortages.

Second, P2P solutions make spending more agile. With advanced solutions, it’s easy to see inventory levels, supplier patterns, and an order’s status. In fact, some solutions, like Vroozi’s, will alert you when orders are delayed or when pricing may be outdated. That way, buyers can easily adjust and purchase quickly through another supplier when supplies run out.

Adopt automation and AI.

Another way to avoid supply chain disruptions is to use AI and automation to free up your work day. P2P solutions that include AI and automation eliminate time-consuming tasks. Automated P2P solutions use machine learning to spot errors, identify spending patterns, and make work more efficient. As a result, you spend less time fixing errors or working on daily tasks and have more time locked in on strategies to avoid supply chain disruptions.

Digitize your P2P processes.

A final way to sidestep supply chain issues is to digitize your P2P processes. Top-tier P2P solutions stream PO, invoicing, spending, and other procurement information into a single platform. That means you can handle POs, track orders, complete approvals, and manage spending in one place. That makes it easier to complete on-time payments, forecast finances, stay under budget, and avoid supply chain surprises.

Learn to Control Company Costs More Effectively

Rising interest rates could soon upset the supply chain, and it’s coming at a time when procurement leaders have a lot to deal with. Sticky inflation and worry about demand drop-offs are all pressuring procurement to control costs more effectively.

Want to gain more control over your company’s costs? Read “Next Stop: Financial Resilience. A Road Map to Cost Control” to learn the secrets to increasing spend control and pushing past economic headwinds.