Procurement’s role in the chemical manufacturing space is full of hurdles, and they seem to be growing larger by the day. Everything from increasing competition and shifting economic policies to supply chain disasters, shipping holdups, and more can tip your procurement plan off course.

However, there are ways to avoid growing procurement challenges within chemical manufacturing and remap your organization’s financial future. Here are five imminent challenges chemical manufacturing faces and the secrets to solving them.

5 Procurement Challenges Plaguing Chemical Manufacturers

Procurement leaders in the chemical manufacturing industry have always faced significant challenges. Now, many of these challenges are intensifying. Here are five procurement challenges that can wreck your long-term procurement strategy:

- Growing competition: Competition is increasing worldwide, putting extra pressure on procurement to cut costs and find discounts. But procurement can’t always see how the company is spending, which contracts are being upheld, and where they can find discounts.

- Shifting economic policies: Many major nations are focusing on domestic production and shying away from certain trade partners or regions. As supply chains reform, it can upend your plans. Without clear spend visibility and open lines of communication with suppliers, you can face major problems.

- Budget setbacks: In chemical manufacturing, staying within budget is essential. If you don’t have strong spend under management or if employees are purchasing outside your purchasing system, you could go over budget.

- Supply chain challenges: Manufacturing procurement teams are all too aware of the $82 million hole supply chain disruptions created in businesses’ finances in 2022. In chemical manufacturing, supply chains continue to shift. Most procurement teams don’t have the supply chain resilience to keep inventory low enough without risking shortages.

- Order mistakes: Order errors and delays happen, but many procurement teams don’t have the visibility or flexibility to adjust when they do. Too often, an order mistake will end up slowing down production, costing more money, and wasting employee time.

How Procurement Technology Can Save Chemical Manufacturers

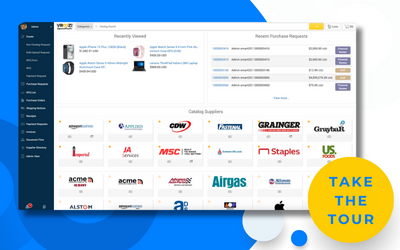

Procurement technology can help leaders in the chemical manufacturing industry navigate the sector’s more pressing challenges. Automated procure-to-pay (P2P) solutions include a digital purchasing marketplace, allowing employees to browse through approved suppliers and make purchases in a few clicks.

Advanced P2P solutions can also automate tasks throughout the P2P process, reduce errors, and make it easy to manage spend. Here are a few ways this type of technology can help chemical manufacturing procurement teams rise above the challenges:

More Transparency and Spend Flexibility

When an intuitive digital marketplace is available, employees purchase from approved suppliers. At the same time, you capture their spend data and gain more control over spend. Ultimately, that gives you full spend visibility, so you can see exactly who your company is working with and which strategic sourcing moves to make.

The platform also keeps your team in close contact with suppliers. When supplies run low or orders are delayed, you can receive alerts and buy from another source. As a result, you can keep inventory low and avoid supply chain disruptions.

Fewer Human Errors

Automated P2P solutions automatically record and label spend data by supplier, location, department, or category. They also complete two- and three-way matching and can identify errors throughout your P2P processes. That all leads to fewer errors and disruptions.

More Time to Strategize

Advanced P2P solutions will complete tasks for you. For instance, AI can auto-generate purchase orders (POs) and match invoice line items to your POs. That frees you up to focus on your procurement strategy.

More Spend Visibility

When employees purchase items through a digital marketplace, quality spend data flows into reports. This digital marketplace eliminates rogue spending and increases your spend under management. It also reveals which suppliers your company is working with throughout the organization so you can identify smarter strategic sourcing opportunities.

More spend visibility also means your company has less compliance and purchasing risk. You can see suppliers more clearly and determine if they operate safely and ethically.

Advanced P2P solutions also automate accounts payable tasks, eliminate manual input, and create financial reports that are easy to review. All of these benefits give you better insights faster, so you can identify errors and avoid going over budget.

Learn How AI is Supercharging Procurement Teams

Procurement technology can help leaders in the chemical manufacturing space overcome the industry’s most costly challenges. But when it comes to the benefits of procurement technology, this is just the beginning. AI is now enabling procurement teams to hit their goals faster than ever. Read our guide, AI in Procurement: Leveraging the Power of AI-Driven Procurement and Invoice Automation, to learn how AI gives procurement leaders an edge.