Strategic sourcing is a process businesses use to obtain the goods and services needed to operate and grow in a way that creates value for the company. While businesses always need supplier partnerships, sourcing has evolved in recent decades beyond simply buying from who offers the best price. Modern sourcing takes a more sophisticated and strategic approach.

Strategic sourcing aims to secure the best possible value for the company by considering the full spectrum of costs associated with procuring goods and services, not just the short-term costs of each purchase. Procurement professionals use their understanding of the market and the business’s strategic needs to negotiate better contracts, save money, and foster strong relationships with suppliers.

In this article, we explore what strategic sourcing is and how procurement software enhances a business’s ability to source strategically, including:

- How strategic sourcing differs from traditional sourcing

- The components of strategic sourcing

- The importance of supplier relationships

- Sourcing challenges and how modern procure-to-pay technology overcomes them

Understanding Strategic Sourcing: A Holistic Approach

Strategic sourcing focuses on identifying suitable suppliers and managing relationships to balance supplier quality, diversity, and sustainability. It restructures buyer and supplier interactions, moving away from relationships based on commoditization and competition and towards a holistic view of spend and supply chain management.

In addition to reshaping external relationships with suppliers, strategic sourcing transforms internal relationships and processes to maximize value. It encourages different departments to collaborate and adopt consistent procurement best practices.

Internal alignment ensures that sourcing strategies are cost-effective and support broader business goals such as innovation, quality improvement, and market expansion.

Technology plays a key role. Modern procurement software enables businesses to collect and analyze comprehensive procurement data. Enhanced spend visibility empowers procurement teams to make informed decisions that maximize value across the supply chain.

In addition to improving data quality and volume, source-to-pay software streamlines and automates many sourcing, procurement, and accounts payable processes, reducing labor costs while enhancing sourcing agility and responsiveness.

Sourcing vs Strategic Sourcing

Sourcing and strategic sourcing are two different approaches to obtaining the products and materials a business needs. Traditional sourcing targets finding the lowest cost per unit. It involves negotiating with suppliers to get the best immediate price for high volumes, aiming for mass discounts.

Strategic sourcing takes a broader view. It considers the total cost of ownership, which includes all operational costs over time, not just the initial price paid to suppliers. Sourcing professionals look at the long-term value and impact of purchasing decisions, considering supplier diversity, supply chain risk, the quality of goods and services, reliability, and the efficiency of the supplier’s delivery and service.

Sourcing vs Procurement

Sourcing and procurement are related, but they are not interchangeable. Sourcing focuses on identifying, evaluating, and selecting suppliers to obtain goods, services, or materials needed for business operations. It aims to build a robust supply chain and get the best contract terms.

Procurement, in contrast, encompasses the end-to-end process of acquiring goods and services, including identifying needs, sourcing, purchasing, inspection, payment, and supplier management.

The Stages of Strategic Sourcing

Strategic sourcing is a methodical process that optimizes an organization’s supply base while improving its value proposition. Let’s explore the key stages of introducing strategic sourcing to a business.

1. Assessment of Current Spending

Strategic sourcing begins with a comprehensive review of the business’s current spending. All expenditures are categorized to understand where and how resources are allocated. It’s essential to comprehensively identify the types of goods and services purchased, the amounts spent, and the suppliers used.

2. Market Analysis

Market analysis researches the supply market for each spend category to understand supplier capabilities, market trends, pricing models, and the competitive landscape.

3. Supplier Evaluation and Selection

Potential suppliers are rigorously evaluated. The evaluation covers various criteria, including quality, cost, reliability, and service levels. The aim is to select suppliers that can provide the best value for the organization.

4. Development of a Sourcing Strategy

Once the company clearly defines its needs and the supply market, it formulates a sourcing strategy. The strategy outlines how the organization will approach the market, manage vendor relationships, and achieve cost savings while maintaining quality and service levels.

5. Negotiation and Contract Development

Supplier negotiations aim to secure favorable terms. Upon reaching an agreement, contracts are drafted to formalize relationship terms, including pricing, delivery schedules, and quality standards.

6. Implementation and Integration

This stage involves rolling out the sourcing strategy, which includes integrating new suppliers into business operations and ensuring that internal processes and the software that supports them are updated to reflect any changes.

7. Performance Measurement and Continuous Improvement

Procurement and sourcing teams continuously measure the sourcing strategy’s and suppliers’ performance. They monitor a broad range of key performance indicators (KPIs) to track whether objectives are met and identify areas for improvement.

8. Risk Management

Risk management anticipates and mitigates potential disruptions in the supply chain. Risk management procedures include:

- Assessing the risk profile of suppliers

- Ensuring supplier diversity

- Monitoring for external risks such as economic shifts or deterioration in supplier performance

- Developing strategies to manage potential risks.

9. Stakeholder Engagement and Communication

Successful strategic sourcing requires active stakeholder engagement, including internal teams and suppliers.

Clear communication ensures that everyone understands the sourcing objectives, the benefits of the strategy, and their role in its execution. Regular dialogue helps to build consensus, manage expectations, and support a collaborative environment that sustains the strategic sourcing process.

Strategic Sourcing and Supplier Relationships

Strategic sourcing does not exclusively find suitable suppliers; it also cultivates relationships that bring long-term value to an organization. These relationships are crucial because they influence quality, reliability, and innovation within the supply chain.

A strong supplier relationship can lead to better prices, improved quality, and new product development opportunities.

There are many ways to categorize relationships, but Kate Vitasek’s 2016 breakdown of relationship types is useful to any business seeking to build supplier relationships appropriate to its spending categories and market conditions.

- Basic Provider Model: This is a transactional approach where the goods or services offered are undifferentiated in the market. Suppliers are plentiful, making it easy to switch if necessary. Competitive bidding is a common feature of this model.

- Approved Provider Model: Similar to the basic provider, this model is transactional but requires suppliers to meet pre-qualification standards or specifications. Suppliers can be replaced if they fail to meet the organization’s needs.

- Preferred Provider Model: Moving towards a more relational approach, the preferred provider model is characterized by recognizing a particular supplier’s value to the business. These suppliers are pre-qualified and demonstrate added value and strong performance, leading to more collaborative relationships.

- Performance-Based/Value-Added Model: This model extends beyond purchasing needs and focuses on suppliers’ ability to drive business improvements. It requires close cooperation and robust controls due to the high level of collaboration between the buyer and supplier.

- Vested Business Model: A collaborative relationship based on mutual success. Vested relationships are suitable for business situations that demand significant shared innovation, which neither party could achieve independently.

By aligning corporate and sourcing strategies, organizations can determine the most appropriate relationship model for each situation. The choice of model depends on the organization’s goals, the nature of the goods or services, and the strategic importance of the supplier.

6 Benefits of Strategic Sourcing

In a competitive and challenging business environment, strategic sourcing is a crucial lever businesses can use to control spending and gain a competitive edge. It offers numerous benefits that enhance a business’s bottom line, operational efficiency, and market positioning.

1. Cost Reduction

Strategic sourcing focuses on obtaining the best possible value from suppliers. That includes leveraging volume purchasing power and negotiation to reduce costs, but it is not limited to the initial purchase price. It extends to the total cost of ownership, including delivery costs, maintenance, and operational efficiency.

2. Improved Quality

By carefully selecting suppliers and establishing clear quality standards, strategic sourcing ensures that the products or services procured meet or exceed the company’s requirements. Better quality leads to better final products, increased customer satisfaction, and potentially fewer returns or complaints.

3. Enhanced Supplier Relationships

As mentioned, building long-term relationships with suppliers is a primary benefit of strategic sourcing. Relationships that foster collaboration and mutual benefit lead to better service, exclusive deals, priority treatment, and a more reliable supply chain.

4. Risk Mitigation

A proactive approach to risk enhances stability and predictability in the supply chain. Techniques such as ensuring the availability of alternative suppliers, thorough market analysis, and contingency planning mitigate risks and reduce the impact of supply chain disruptions, price volatility, and supplier performance degradation.

5. Increased Efficiency

Strategic sourcing streamlines procurement processes by standardizing how goods and services are procured. It reduces complexity, accelerates procurement cycles, and minimizes administrative overhead, leading to more efficient operations.

6. Competitive Advantage

With optimized costs, improved quality, efficient processes, and a robust supply chain, companies implementing strategic sourcing can gain a significant competitive edge in their market. Their sourcing advantage produces better pricing, higher quality products, and more responsive customer service delivery.

Challenges Implementing Strategic Sourcing

Strategic sourcing is key to managing spend and optimizing the supply chain. However, when businesses apply strategic planning to sourcing processes, they face challenges. They find it difficult to transform the theoretical benefits into concrete processes and cost improvements.

Every business is unique, and each will face challenges determined by its market, supply needs, and the expectations of internal and external stakeholders. However, there is a class of challenges that almost all businesses looking to implement strategic sourcing experience.

- Low-quality data and a lack of spend visibility: This issue often arises from disparate data sources and the absence of a centralized system for tracking spending. Companies may have multiple systems or databases that don’t share information, leading to inconsistent or incomplete data. Additionally, there may be a lack of standardized processes for recording spend data, resulting in inaccuracies that cloud the overall spend picture.

- Poor contract compliance: Many businesses struggle to enforce on-contract spending. One cause of low contract compliance is employees’ difficulty accessing a marketplace of approved suppliers. If purchasing through approved channels is cumbersome or inadequately communicated, employees bypass it in favor of more convenient but non-compliant options. Another cause can be a lack of understanding of the importance of compliance, leading to indifference or resistance to following established procedures.

- Limited spend under management: This challenge can stem from a lack of clear procurement policies or the absence of a centralized procurement function. When different departments or business units make independent purchasing decisions without coordination, it leads to fragmented spending. Additionally, a lack of technology that centralizes and provides visibility into all spending can prevent organizations from effectively managing their spend.

- Error-prone manual procurement processes: Manual sourcing and procurement processes are not only time-consuming but also susceptible to human error, which can result in incorrect orders, overpayments, missed discounts, and damaged relationships with suppliers. Manual processes lack the cohesive oversight to catch errors, leading to a compounding of issues over time.

How Procurement Technology Helps Businesses to Overcome Sourcing Challenges

As strategic sourcing has grown increasingly prevalent, so has the adoption of source-to-pay, procure-to-pay, and procurement automation solutions that help businesses overcome the challenges outlined in the previous section.

Procure-to-pay software streamlines the purchasing process from the initial decision to the final payment. For example, it provides a unified marketplace of approved suppliers and intuitive interfaces for everyday procurement tasks, including purchasing, approvals, and analytics.

Procurement automation automates creating and processing purchase requests, purchase orders, and invoices. It accelerates the purchase cycle while ensuring purchases align with company policies and supplier contracts.

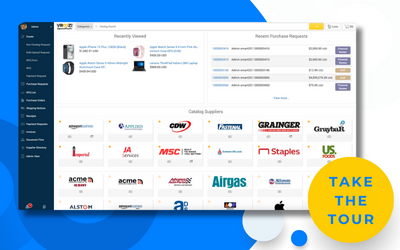

Let’s look at some of the ways a procure-to-pay system like Vroozi can help businesses overcome their strategic sourcing challenges.

- Improved Spend Visibility: Procure-to-pay systems offer real-time tracking and reporting features that comprehensively reveal an organization’s spending. Improved visibility allows businesses to analyze spending patterns, identify cost savings, and make data-driven decisions that align with their strategic sourcing goals.

- Increased Spend Under Management: Centralizing procurement activities ensures greater monitoring and management of a company’s total spend. Increased oversight helps businesses to leverage their total buying power and enforce procurement best practices across the organization.

- Higher Levels of Contract Compliance: Procure-to-pay platforms facilitate compliance by making it easier for employees to purchase from preferred suppliers at negotiated rates. The system can automatically direct users to the correct contracts and ensure that purchases adhere to agreed-upon terms, reducing maverick spending.

- The Elimination of Manual Processes: Automation eliminates the need for manual entry and paper-based processes, reducing the risk of errors and inefficiencies. Streamlining procurement tasks saves time and allows procurement departments to devote more resources to strategic sourcing initiatives.

Vroozi is a cloud procure-to-pay software platform that empowers businesses to streamline, optimize, and reduce the cost of sourcing and procurement. Our modular system integrates a comprehensive range of procurement tools, including:

- A digital supplier marketplace supporting supplier static and punch-out catalogs

- eProcurement with ERP integration

- Purchase order automation

- AP invoice automation

- Digital payments

To see Vroozi in action, experience a live version of the app or request a personalized walkthrough from one of our team members.