The recently introduced tariffs on US imports—and retaliations by the governments of affected countries—present an escalating challenge for global organizations.

The impact of tariffs on profitability and supply chain resilience is already beginning to reshape how businesses operate. To counter rising costs, companies must look to improve operational efficiency and build more secure supply chain networks.

Procurement is one of the most affected areas and thus offers one of the biggest levers you can pull to mitigate the impact of tariffs on your organization.

In this guide, we’ll break down how tariffs affect the procurement sector and explore five effective strategies for mitigating the impact of tariffs in procurement.

How tariffs impact the procurement sector

Tariffs are taxes imposed by a country’s government on imported goods. They’re usually established to increase the cost of foreign products, grow government revenue, or protect domestic products from international competition.

The Trump Administration recently increased tariffs on almost all foreign imports to the US, ranging from a baseline tariff of 10% for certain regions to a 104% levy on all Chinese goods. Many countries are retaliating with tariffs of their own for goods exported from the United States.

For the procurement sector, this presents a multi-faceted challenge comprising:

- Higher landed costs

- Supply chain instability

- Administrative complexity

- Longer lead times

- Inventory management challenges

- Reduced supplier options

To mitigate the bulk of these risks and ensure continued supply chain stability in the face of potential future tariff hikes, businesses must look at internal cost-saving opportunities and efficiency gains.

5 ways to mitigate the impact of tariffs in procurement

Keeping ahead of global economic changes is critical to remaining competitive and profitable. Smart organizations are prudent in mitigating the risks presented by new tariffs and focus on staying aware of any changes that may affect international trade.

Five strategies you can leverage to mitigate the impact of tariffs in procurement:

- Diversify your supply chain and negotiate costs

- Identify new components and re-engineer products

- Increase contractual protections to address tariff changes

- Optimize internal procurement processes

- Improve internal and external collaboration

Let’s dive into the details.

1. Diversify your supply chain and negotiate costs

Supplier diversification and cost negotiations reduce your dependency on single regions or suppliers vulnerable to new tariffs. These strategies create competitive tension that can help spread the risk across your supply chain and provide a leverage point for better negotiations.

To establish greater supply chain diversification and effectively negotiate costs:

- Proactively source and onboard suppliers in countries with lower rates.

- Explore nearshoring and reshoring opportunities.

- Renegotiate existing contracts with suppliers in tariff-affected regions and leverage tariffs when negotiating import costs.

- Explore options for cost-sharing and absorption.

- Identify alternative relationship efficiencies, such as longer-term commitments, that can be leveraged for better pricing.

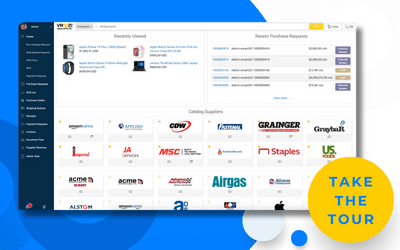

Modern procurement technologies, such as Vroozi’s intelligent spend management software, help simplify and streamline the process of comparing and onboarding suppliers. Vroozi’s supplier portal and dynamic supplier marketplace enable you to quickly identify and qualify new suppliers while centralizing critical supplier information for faster and more informed diversification decision making.

2. Identify new components and re-engineer products

If you produce goods comprising components from tariff-affected regions, you can reduce the burden of tariffs by changing the components within a product’s bill of materials (BOMs).

Analyze your existing BOMs to identify component substitutes—alternative materials or components sourced from regions with lower tariff rates—to potentially lower the total cost of goods manufactured without sacrificing quality or functionality.

Note: This requires working directly with research and development and engineering teams and meticulously analyzing HS code classifications to determine how product design changes may shift a product into an HS category with lower tariff rates.

3. Increase contractual protections to address tariff changes

Proactive supplier contract management provides a threefold solution to mitigating the impact of tariffs in procurement. It achieves this by:

- Preventing ambiguity when tariffs are changed

- Reducing disputes that may harm supplier relationships

- Establishing legal clarity and predictability

Review your existing supplier contracts to identify any clauses that address changes in law, taxes, or duties. Ensure that such clauses use clear language and align risk and responsibility for duty payment and customs clearance with your internal sourcing strategies.

Pro Tip: When creating new contracts, make it clear during negotiations (and within the contract) which party bears the financial responsibility for new or inflated tariffs.

4. Optimize internal procurement processes

Increasing operational efficiency unlocks cost-savings that can help you absorb unavoidable tariff costs while protecting your profit margins. Optimizing procurement processes is a good place to start, as many tasks can be performed more efficiently with the right technology and workflows in place.

AI-powered procurement software, for example, offers many opportunities for efficiency gains.

- Process automation: Procure-to-pay software like Vroozi can reduce processing time and costs in procurement by automating frequent tasks such as purchase requisitioning, approval workflows, and sourcing.

- Enhanced spend visibility: Real-time procurement analytics provide clarity and actionable insights across spending performance, helping to identify areas for improvement and cost-saving opportunities.

- Catalog management: A centralized supplier marketplace supports more cost-effective purchasing by making it easier for teams to compare suppliers, buy from preferred vendors, and compare pre-negotiated contracts.

Procurement process optimization is an evergreen strategy that fosters a culture of continuous improvement. By seeking to improve efficiencies across the board, your organization will be well-positioned to operate more profitably regardless of the global trade environment.

5. Improve internal and external collaboration

The best way to ensure all tariff implications are addressed holistically is a systemic approach to risk mitigation. This means establishing cross-functional risk management strategies for new tariffs and improving collaboration and communication with your existing suppliers.

Centralizing spend management and purchasing data through a unified system such as Vroozi provides the visibility and accessibility required to collaborate effectively between different functions within your organization. Clear communication channels enable procurement to operate cohesively with other departments—such as Finance, Legal, and Sales—to develop integrated strategies that align key objectives from each area.

To see how Vroozi helps organizations build better workflows and streamline the approval process, try the software for yourself today with our free interactive product tour.